Slide title

Milking Cows & Storing Milk

Button

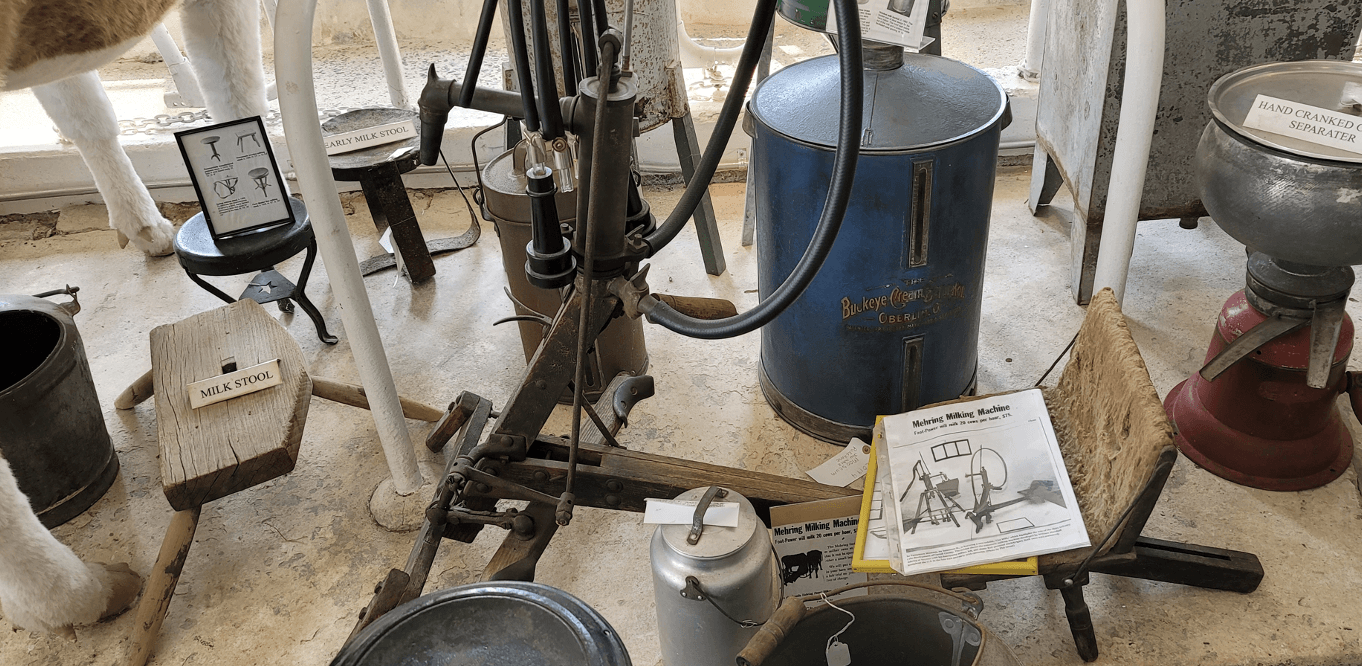

Different types of equipment used to milk cows

At the bottom of this page is a link to a YouTube video on milking a cow by hand and also an up-to-date video on modern milking practices, from Dairy Max, a 40-year-old regional dairy council from a consortium of states in the southwest U.S.

The MOOseum has on display a variety of milking related equipment used on Montgomery County dairy farms. With over 500 dairy farms in Montgomery County in the middle of the 20th Century, they offered a variety of products. Some, like the James and Macie King Farm, shipped their milk to processors, such as Thompson Dairy in Washington, D.C., where the milk was processed into milk bottles, butter, cream, etc. Others milked their cows, bottled the milk, delivered it to their customers, cleaned the empty bottles and repeated this process day in and day out. Some were creameries where they sold their cream, butter, ice cream. As a result, not all farms had all of the different types of equipment found in this section.

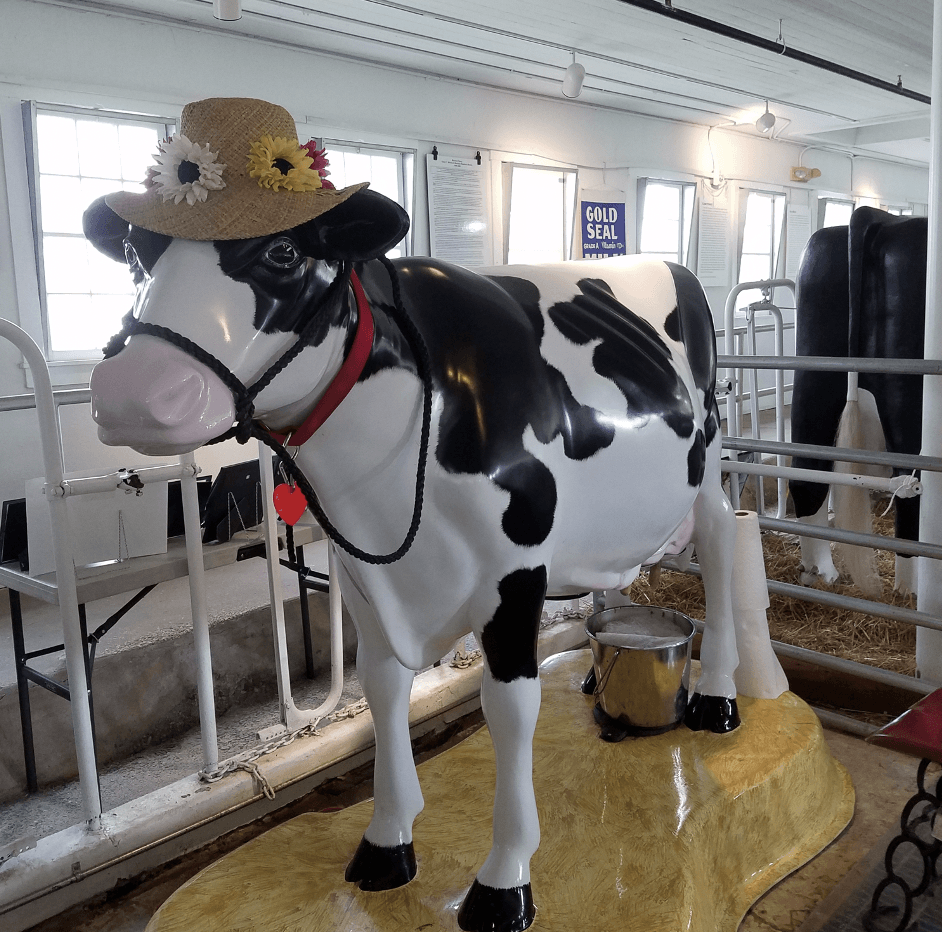

In this section of the MOOseum are different types of milkers from doing it by hand – or foot in the case of this rare model!- to vacuum milkers to robotic milkers.

In this rare “hand milker” shown in the photograph on the bottom left, the farmer would sit on the seat low to the floor and press his feet back and forth to cause a vacuum effect to gently bring the milk out of the cow teat.

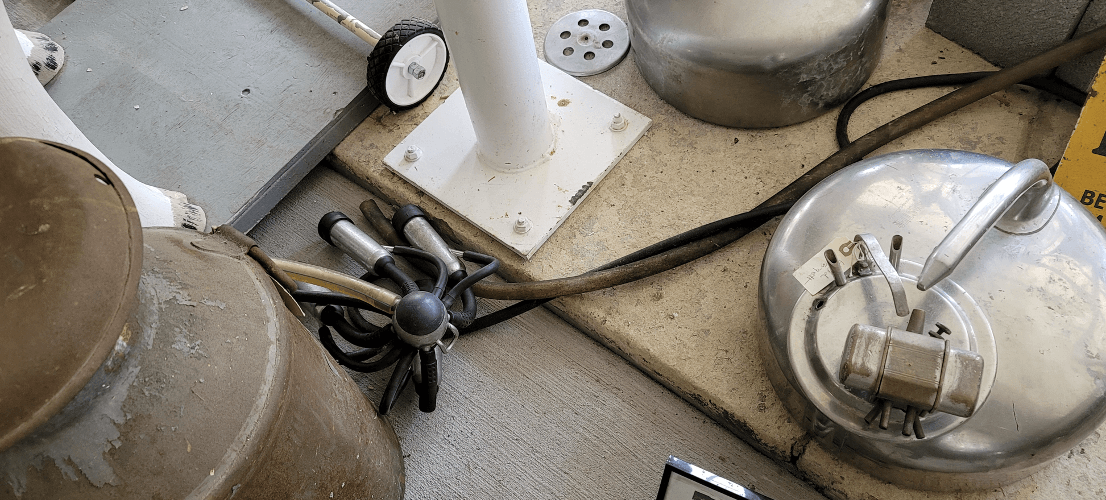

More common vacuum milkers looked like the photo on the bottom right. They were run on batteries or electric if available, and the cups were attached to the cow's teats with the on/off effect causing a gently pressing of the teat to lower the milk down to exit. Once the container was filled, the milk would be transferred to a 10-gallon milk can, and carried to a cooler to begin the process of cooling the milk.

HAND MILKER

VACUUM MILKER

As electric became available, dairy farmers upgraded vacuum milkers so they were attached to pipes that carry the milk directly to the dairy building/milk house to be stored in a bulk tank. This avoided having to transfer the milk to a 10-gallon milk can and reduced work on the farmer. This is the method used at this farm, the James and Macie King Farm, when this barn was built.

BULK TANK

This bulk tank is one of the smaller models. On the James and Macie King Farm the bulk tank was in the dairy building/milk house which now houses the library/research room for the MOOseum. Milk was carried from the long barn via pipes and directly deposited in the bulk tank. There were blades in the bulk tank that would gently turn to cool down the milk. Once a day or every other day, a truck would drive up the farm road and syphon out the milk to take it to be processed.

WASHING MILK CANS

These washing tubs from the Toth farm, #68 on the MOO Map, were found on many farms. In the early 1900’s milk cans were washed and sterilized after each use. One side of the tub had water for washing, and the other side might contain some bleach in the water for sterilizing. This prevented the spread of bacteria. The clean milk cans were placed on a rack to dry and stored ready for use.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

KING BARN DAIRY MOOSEUM LOCATION

South Germantown Recreational Park

18028 Central Park Circle

Boyds, MD 20841

MAILING ADDRESS

King Barn Dairy Mooseum

PO Box 76

Boyds, MD 20841-0076

SUBSCRIBE TO OUR NEWSLETTER

All Rights Reserved | King Barn Dairy Mooseum

disclaimer